Independent Steam Trap Surveys

More than a mechanical function check, it is a process check.

Each steam trap is evaluated and checked under the following headings;

- Mechanical function.

- Suitability for the application.

- Installation.

- Location, pipe sizing & configuration.

- Steam & condensate loads.

- Process conditions.

- Energy efficiency.

- Process efficiency .

- Safety.

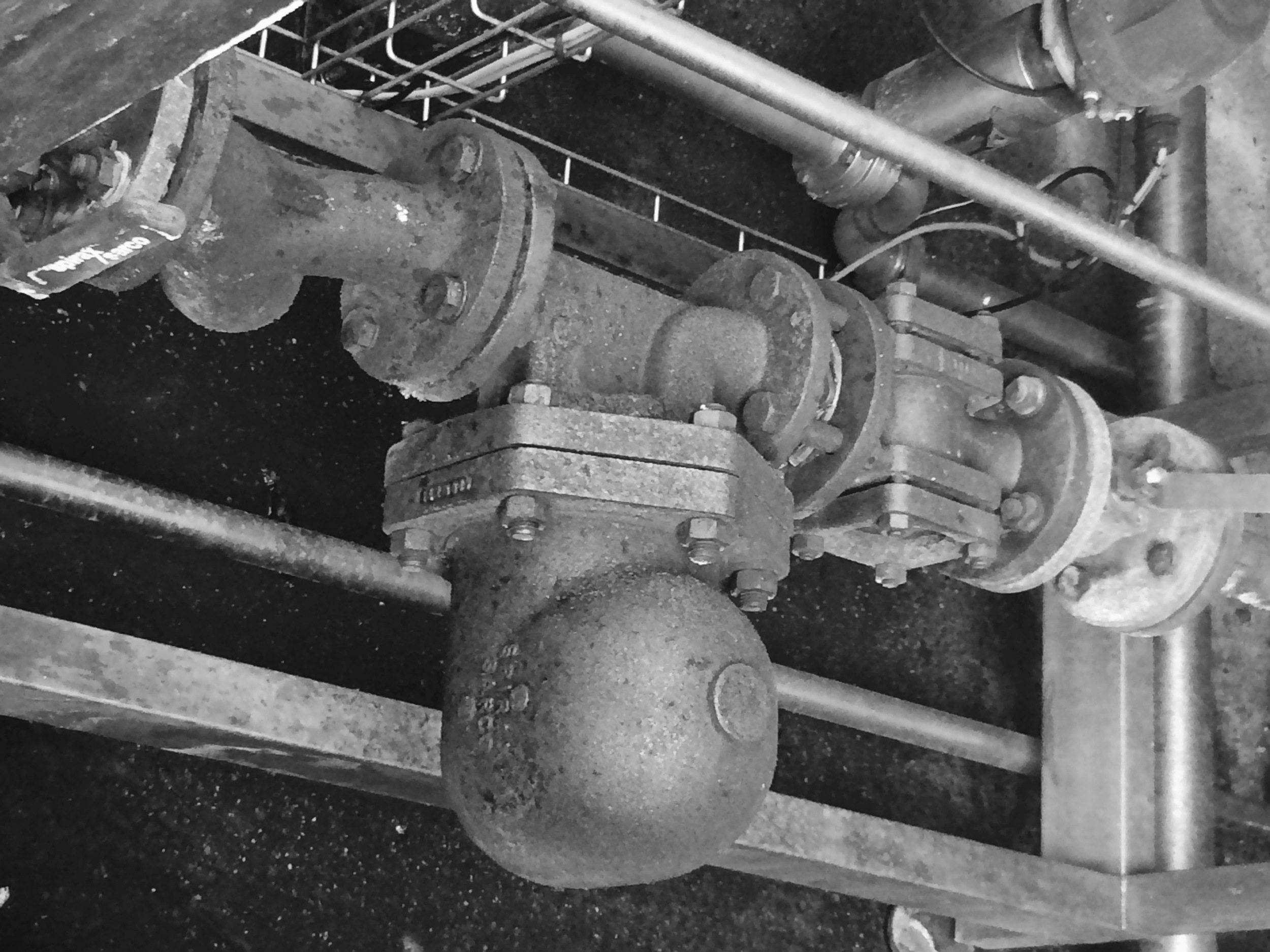

The correct mechanical function of a steam trap is vital. Of equal importance is; trap suitability for the application, correct installation, it's location, process flow conditions and discharge conditions.

Any of the above factors can reduce the performance of process even if a steam trap is mechanically functioning ok.

A simple example that is often found during surveys; On a heat exchanger unit, the steam trap is functioning ok but the temperatures and ultrasonic readings are relatively high, this is a clear indication of one of two things.

- Fouling of the heat exchanger.

- The process is being operated outside of original design parameters.

When surveying steam traps Rackard Steam evaluates all the related elements.

____________________________________________________________________________________________________________________

Energy Losses

One distribution line steam trap failure on a typical 10 barg steam plant operating 4,000 hrs pa will cost €5,300 in additional fuel costs. (Natural Gas @ €0.033 kWh.)

On average a steam trap has a service life of 5 years. Systematic replacement of steam traps while effective is costly. If steam traps are venting into a common or pressurized condensate return line it can be difficult to determine their condition by normal means. Using the latest ultrasonic equipment and analysis software Rackard Steam + Biomass Services can accurately determine the effective condition of a steam trap thereby saving on fuel and needless replacement costs.

We do not sell steam traps, our sole focus is to give the client the best information and value for money.