Babecock & Wanson 15 MW Thermal Oxidizer Upgrade

Rackard Steam were requested by the client to design and specify an upgrade 15 MW Babecosk & Wilson Thermal Oxidizer with heat recovery. This included the specification of new and replacement instrumentation and the replacement of the existing controls. New control logic was required to integrate the Oxidizers waste heat boiler into the existing steam system and integrate it with other vapor producing and reducing plant. The new control elements were also required into integrate with a new Saacke dual fuel burner and control panel.

The Oxidizer was successfully commissioned in July 2016

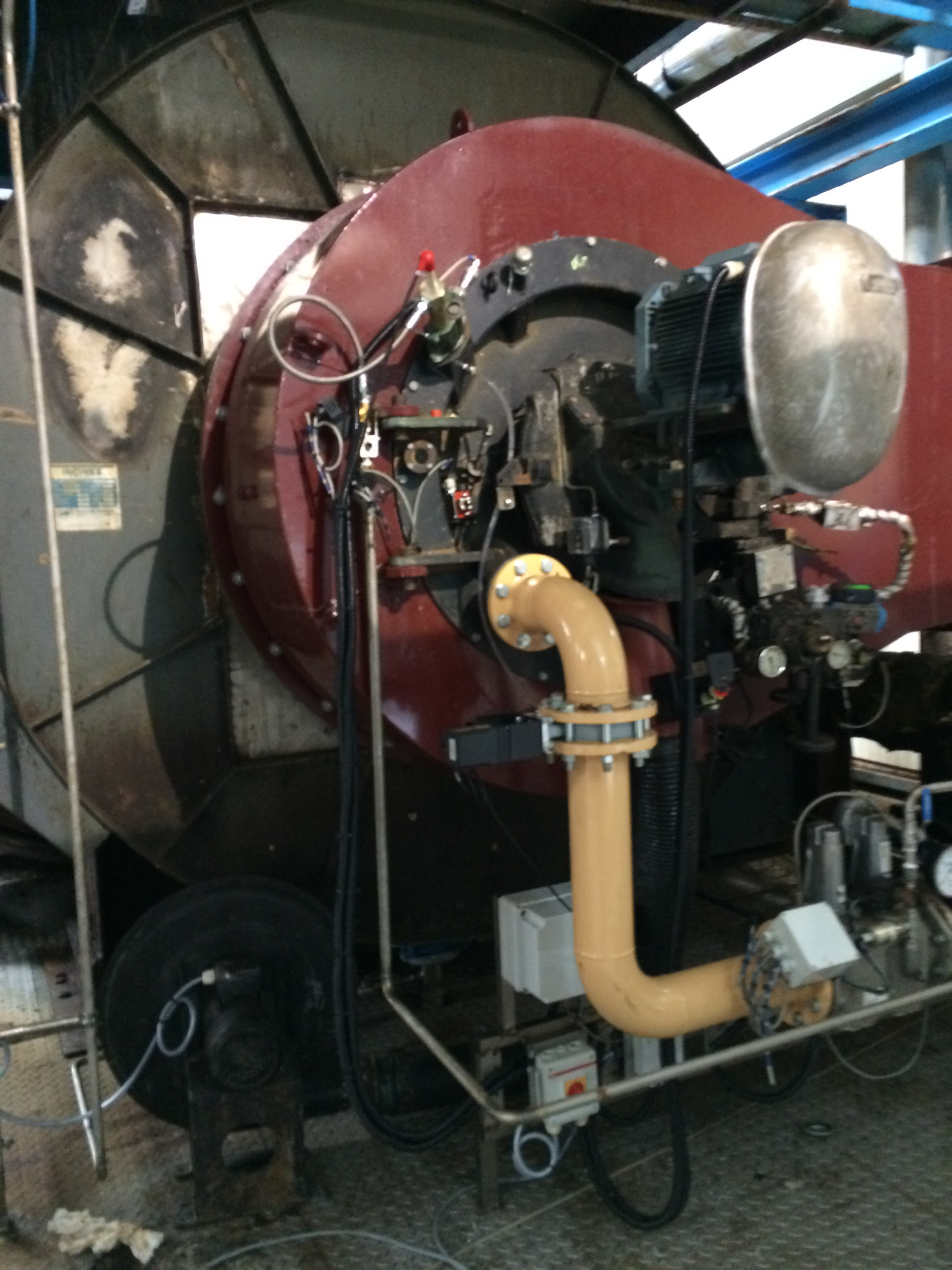

New Saacke dual fuel burner and modified air register

Feature 1

Rackard Steam designed the modifications to the existing air register and internal refractory

Modifications to the refractory

Old Babecock & Wilson Control Interface

Controls

The existing panel was not fit for purpose, a new panel was specified with a Siemens S7 plc and Siemens VSDs running combustion air fans, feed water pump, ID fan and fuel pumps. Boiler water level controls were upgraded and safety interlocks incorporated with the Saacke Scanview Burner control system.

New Siemens HMI with new graphic control interface by Rackard Steam

TO panel customized commisioning interface

Automation

Ensuring safe efficient operation and a user friendly interface were essential for the ongoing safe and efficient operation of the Oxidizer..

Integration with existing systems was an essential part of the project.